Plastics and Metal Tooling

We can create tips, tools, molds, fittings, and any other items needed for your manufacturer to quickly and efficiently "tool up" the assembly line to create your product.

Prototyping Soft & Hard Tooling

Hard tooling and soft tooling differ primarily in material durability and cost. Soft tooling, such as urethane, is cost-effective for smaller production runs but tends to wear out faster. Hard tooling, such as aluminum, involves a higher initial cost but provides greater durability, making it ideal for large-scale manufacturing.

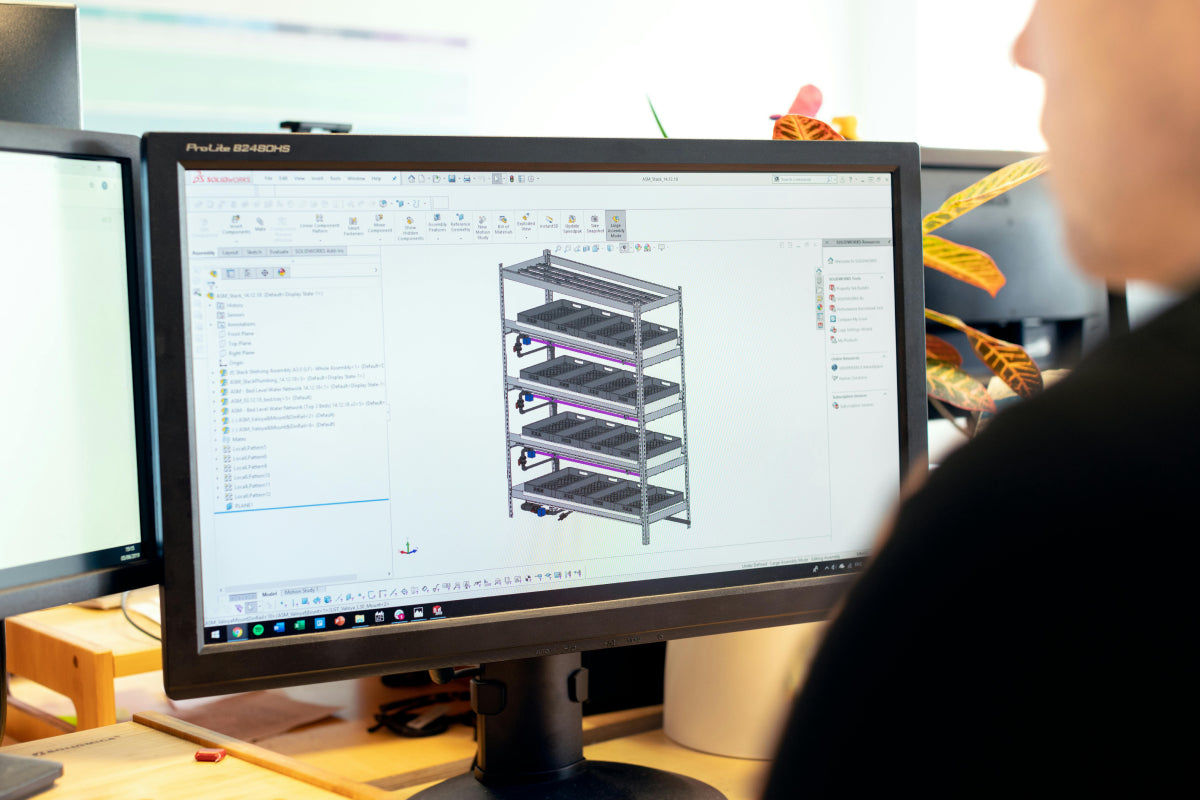

SolidWorks, Pro-E, 2D and 3D drawings

(CAD) Computer Aided Design, (CAM) Computer Aided Manufacturing & (CAE) Computer Aided Engineering Software, for creating illustrations or 3D models.

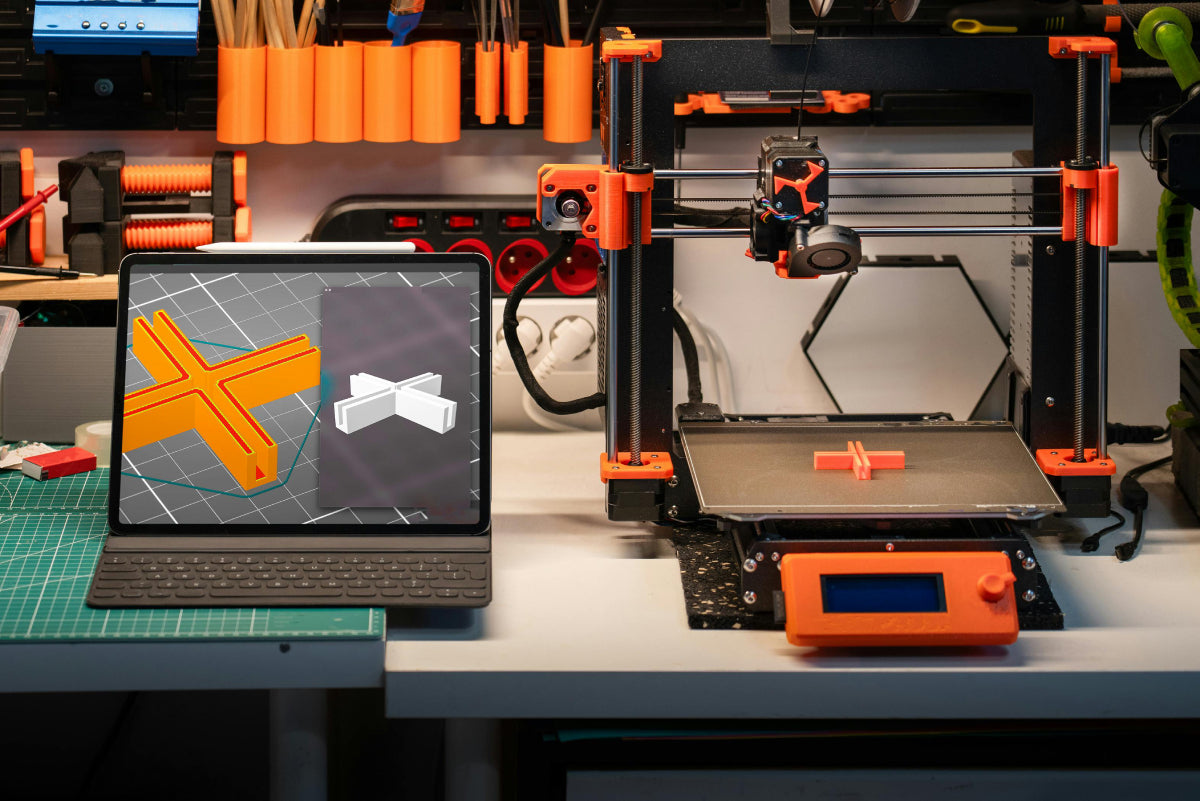

3D Printing

Our in-house 3D printing ensures your project is completed quickly, accurately, and to the highest standards.

Injection Molding

Injection molding is a manufacturing process that involves injecting molten plastic into a custom mold, rapidly cooling it to solidify the material, and efficiently producing large quantities of parts at a low cost per unit.

Diecast

This process closely resembles injection molding but typically utilizes metal instead of plastic to produce durable, high-quality metal components.

Packaging

KAI Engineering can assist with packaging design and creation services, delivering a complete, end-to-end solution for your product development needs.