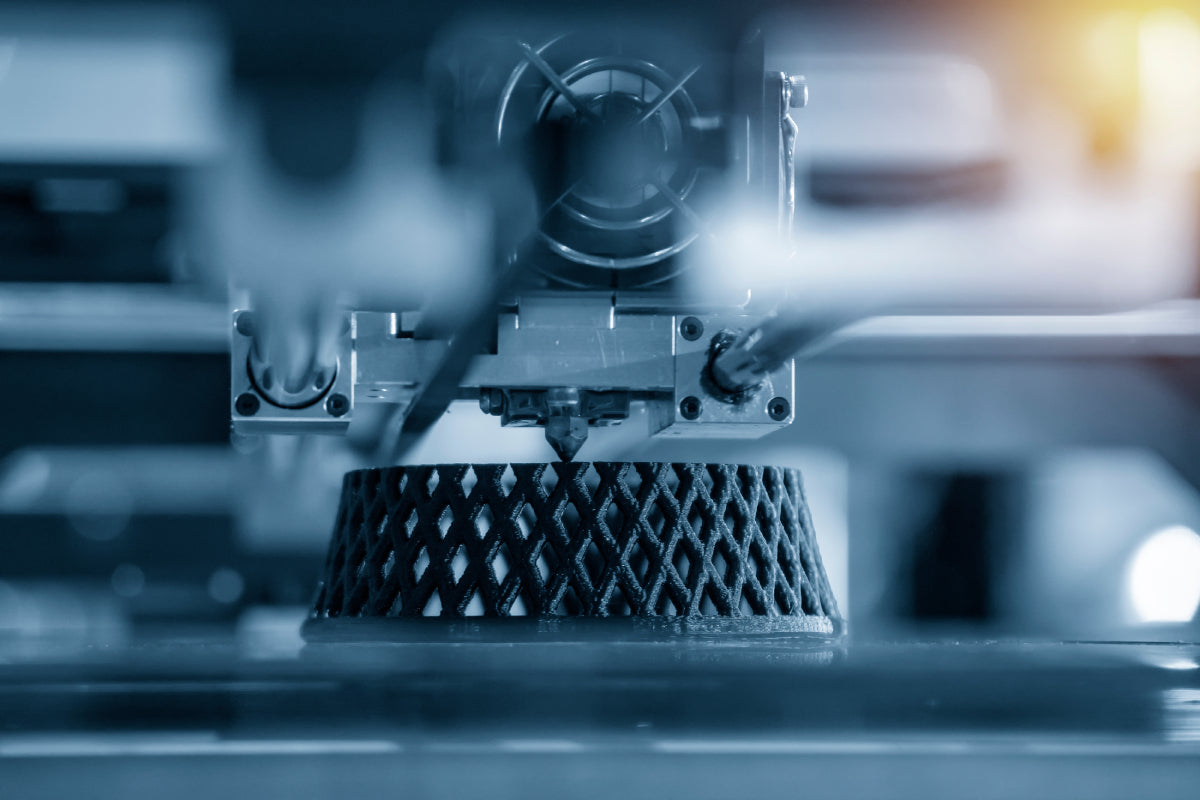

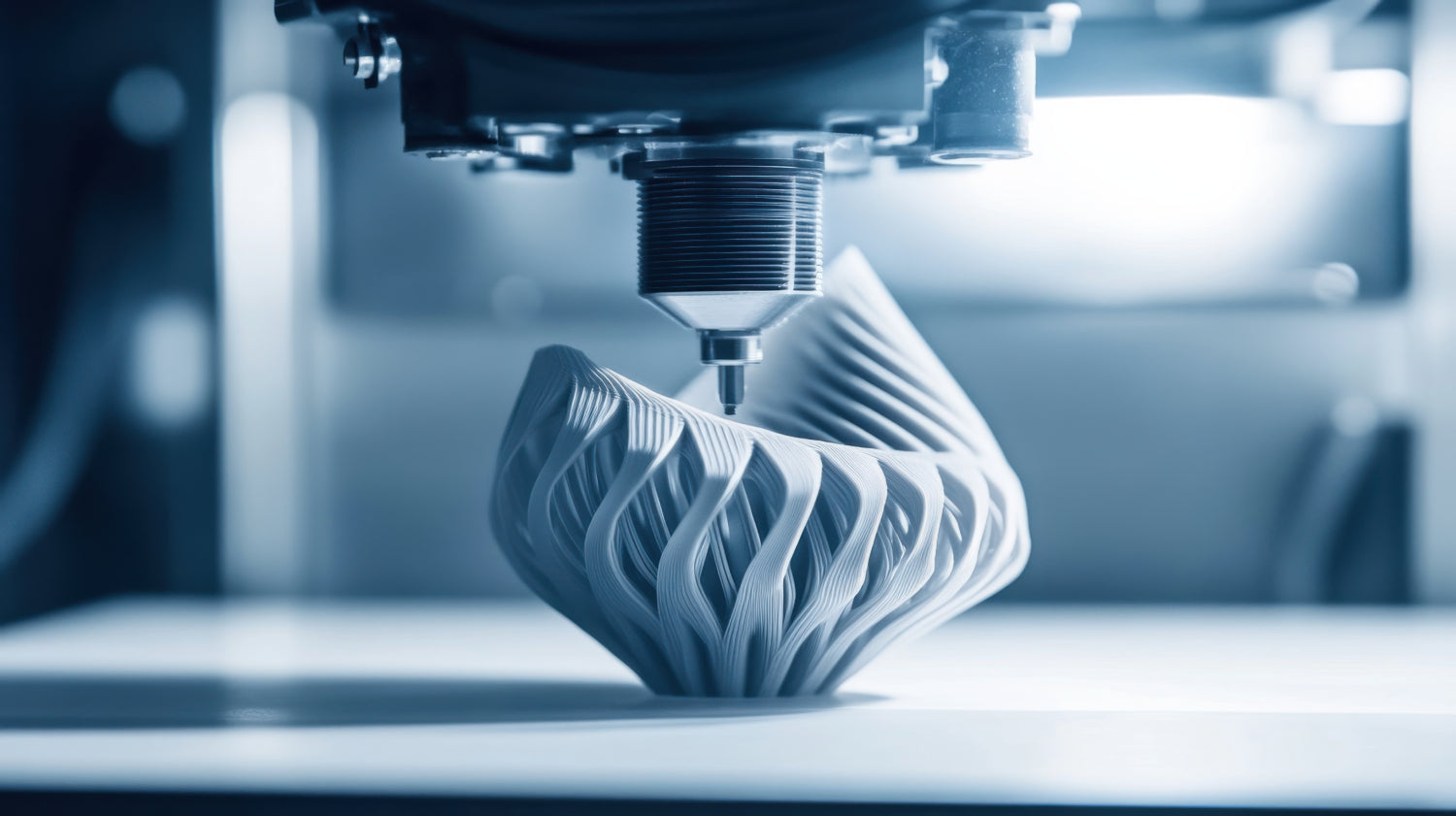

3D Printing (Plastic & Metal)

At KAI Engineering, we deliver 3D-printed parts of the high test quality and precision, utilizing industry-leading equipment and cutting-edge technology. From rapid prototyping to end-use manufacturing, we produce and expertly finish components ready for immediate application.

SLA (Stereolithography)

Stereolithography is a form of 3D printing technology used for creating models, prototypes, patterns, and production parts in a layer by layer fashion using photochemical processes by which light causes chemical monomers and oligomers to cross-link together to form polymers.

SLS (Selective Laser Sintering)

Selective laser sintering is a 3D printing (or additive manufacturing [AM]) technique that uses lasers to "sinter" (a natural chemical process in mineral deposits where the atoms fuse to form one solid piece), metals, ceramics, plastics or other materials. Since this process does not need to reach melting point, it is great for materials with high melting points like tungsten.

Selective Laser Melting (SLM)

Selective laser melting, also known as direct metal laser melting or laser powder bed fusion, is a rapid prototyping, 3D printing, or additive manufacturing technique designed to use a high power-density laser to melt and fuse metallic powders together.

- Soft Parts

Soft Parts, such as silicones and other highly elastic materials. - 3D Modeling & Design Services

- 3D Scanning

KAI Engineering delivers rapid turnaround times with exceptional precision and expertise.

Looking for 3d Printing?

Check us out at:

www.kai3dservice.com